Preformed guy grip is a recognized tension clamp used to fix the wire on pole towers, iron towers, and microwave towers which can replace the wedge-shaped clamps commonly used to fix the wires on line towers. It grips the conductors, grounds wires and used for other fiber optic applications.

The unique design makes the structure of the preformed guy grip simple and reliable.

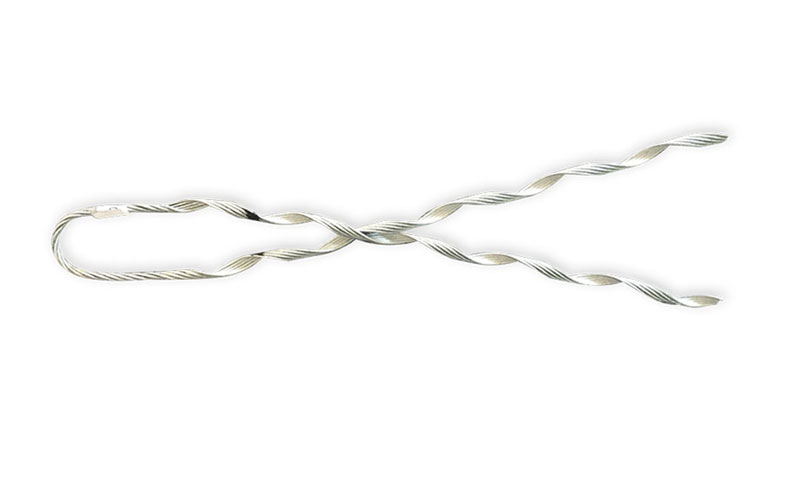

Components are added to the clamp as required by the application needs. The legs of the pull handle are helical and hold the wire in place with each turn. Besides, the strands have fixed points and are related to the grip of the person. When it is wrapped around a conductor or product like ADSS cable, say a guy wire, the grip will be strong to avoid slippage between the guy clip and the conductor.

After installation, the empty tube formed by helical legs of the preformed tension clamp twisting together is wound on the cable to produce a strong grip. The twisted ring is used to fix it on the ground anchor or tower pole.

FEATURES

1. The guy grip has high strength and reliable grip.

The grip strength of the tension clamp is not less than 95% CUTS (calculated breaking force of stranded wire).

2. It is available in various sizes.

3. The force of the guy grip on the twisted wire is even, without damaging the twisted wire, which improves the anti-vibration ability of the twisted wire and greatly prolongs the service life of the wire.

4. Simple installation and convenient construction. The construction time can be greatly shortened, and the operation can be completed by one person without any special tools.

5. The installation quality of the tension clamp is easy to guarantee, and can be inspected with the naked eye without special training.

6. Good corrosion resistance, high-quality materials are selected. Tuolima commonly uses galvanized steel and aluminum material, which ensures that the tension clamp has a strong ability to resist electrochemical corrosion.

7. An optional anti-theft ring can effectively solve the problem of anti-theft.

Most of the raw materials used to make preformed guy grips include aluminum and galvanized steel. In addition to the conventional production process (see the next article), the preformed tension clamp produced by Tuolima needs to go through additional multi-step processes, such as raw material chemical composition testing, ultrasonic cleaning, grip strength and tensile testing, to ensure the material quality and standard weight of the product, plus strict production process to meet customer installation requirements.

Related Blog

Related Products