Author: C

Time: 2022/8/17

The formation of a satisfactory preformed dead-end includes two processes:

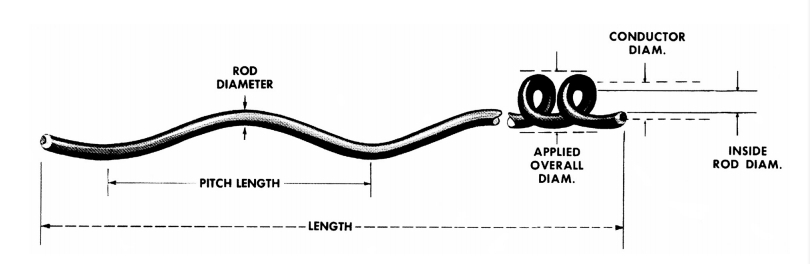

Conductor diameter

Inside rod diameter

Applied overall diameter

Rod Diameter

Pitch length

Length

Generally speaking, according to the model name and span of the cable used (the distance between two poles), we can tell the approximate weight of the cable, so as to judge the size range.

For example, a 100m span ADSS cable (G.W.>100kgs): 5 steel wires with corresponding steel wire diameter 3.0mm; Or 6 steel wires with diameter2.3/2.5mm.

Remark: it is necessary to consider the natural environment: wind speed, icing degree, etc.

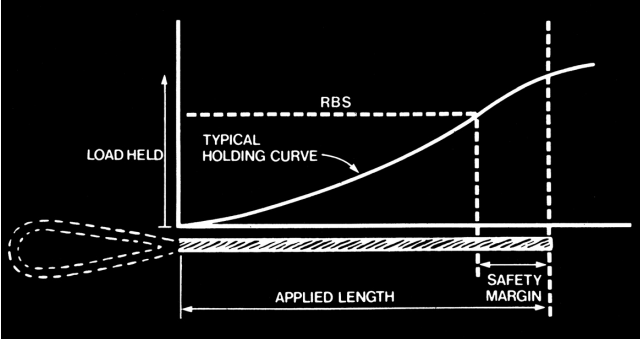

Typical holding strength curve illustrates that the holding strength and the applied length are not proportional. A safety factor of approximately one pitch length is designed into the preformed dead-ends. In order to make the preformed dead-ends have a pressing force on the cable, the overall rod diameter(see picture1) after molding will be lower than that after installation.

Related Blog

Related Products